We have been working with the University of Liverpool for almost 10 years and previous projects include installing their district heating network and an award-winning project which saw us transform a derelict, Grade II former mortuary building into a state-of-the-art CHP energy centre. In our latest project, we are delivering an energy centre and district heating network to supply the University of Liverpool's new student halls of residence.

Greenbank Student Village is part of a £250m masterplan to regenerate and expand upon campuses across Liverpool. The 20.8 acre Greenbank Student Village is currently undergoing a redevelopment including the regeneration of the 18th century building, Greenbank House, which was left to the University of Liverpool by the Rathbone family.

Once complete, Greenbank Student Village will provide 1,361 en suite bedrooms, leisure facilities, social spaces and a library/study area to accommodate bustling student life. The University of Liverpool want to “create a community for its stakeholders that operates in an environmentally sustainable, economically feasible and socially responsible way." Therefore, coming up with a sustainable energy solution was key to this development.

In further developments, the University wanted to continue to reduce their carbon footprint and deliver high quality, sustainable buildings. Once Greenbank Student Village is complete, accommodation will have increased by 40% so the new energy centre needs to meet the increased demand of students living on the site.

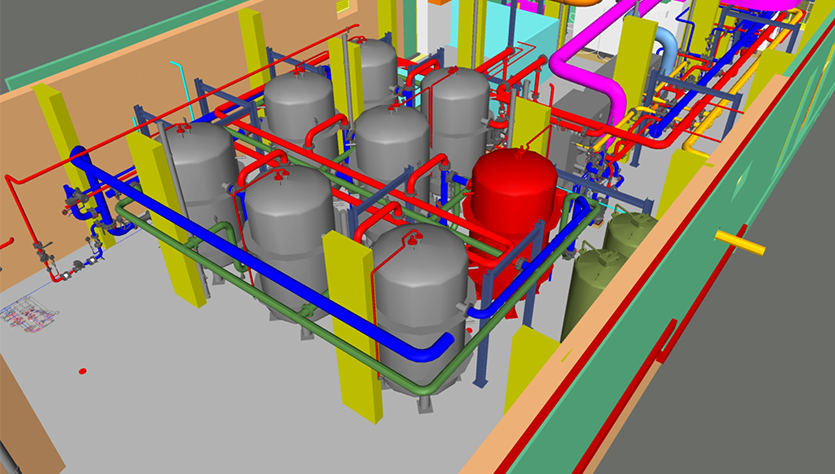

Continuing our longstanding relationship, the University of Liverpool selected Vital Energi to design and build the energy centre and district heating network to supply Greenbank Student Village. The University had a low noise specification which needed to be adhered to as the energy centre is situated in the basement of one of the student apartment blocks.

In order to keep the plantroom noise break out to less than 45dBA at 1m outside the energy centre, Vital Energi came up with a bespoke noise attenuation solution. This included installing the 600mm acoustic louvres and 155m2 of 100mm thick lamaphon acoustic lining to the ceiling to achieve NR30 noise levels in the student’s living rooms above the energy centre. Additionally, we will be installing a Hoval boiler with an acoustic hood, 25mm of acoustic lining on the CHP’s ventilation ductwork and vibration isolation on each piece of equipment, which will all be floor mounted and not suspended from the ceiling. The CHP flues will have stage 4 attenuation and the boilers will have single stage attenuation. Once the energy centre is complete, a noise assessment based on Fischer Acoustics methodology will be carried out to measure if the plantroom meets the 45dBA at 1m specified noise limit.