As part of the planned evolution of the King's Cross energy centre, Vital Energi were chosen to develop, deliver and operate the cooling energy centre and network. This was an important step in the development's progress as it allows the overall energy solution to become a trigeneration scheme and operate more efficiently.

Vital Energi have been involved in developing the King’s Cross energy strategy since 2009, creating an energy generation and distribution solution which evolved alongside the development, ensuring optimum performance at each stage.

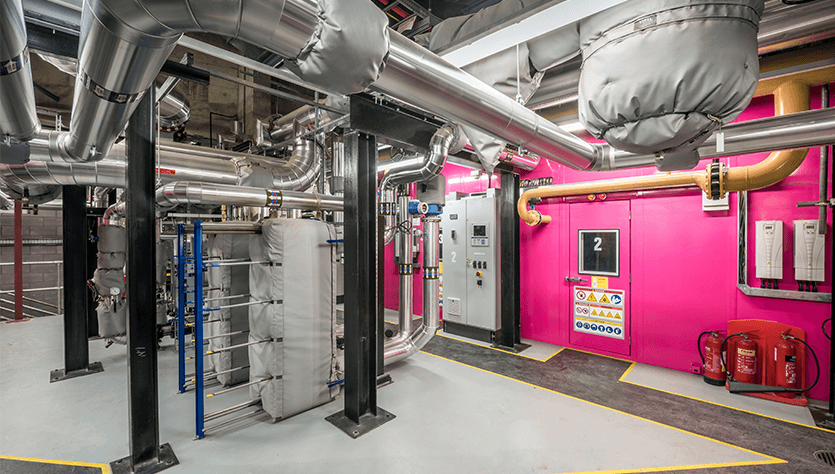

One of the planning stipulations attached to the 67-acre London site was that the energy infrastructure would produce low carbon cooling, in addition to heat and power, making it a tri-generation scheme. Vital Energi were commissioned to perform a feasibility study and designed a solution which took waste heat from the CHPs in the existing energy centre, during the warmer summer months when it wasn’t being used, and converted it into cooling for the surrounding buildings via an absorption chiller.

The project was made challenging in several respects, with one being the unusual shape and size of the footprint the new “cooling pod” would be situated on and the second was the proximity to the HS1 train line which brings strict restrictions which are backed up by severe financial penalties.

The initial concept for the development would have seen traditional, individual cooling solutions set up in each building, but Vital Energi were asked to develop a proposal for a central cooling pod, which would fulfil the tri-generation requirement for the project. The site of the Cooling Pod was the last area to be designated in the plans and makes use of a crescent shaped piece of land situated between the HS1 Channel Tunnel Rail Link and an office development.

This irregular, curved 120m long space varied from 6-8 metres wide. Our designers created a two-story solution with an optimal plant layout which not only accommodated all the necessary equipment, but allowed for safe operation and maintenance going forward.