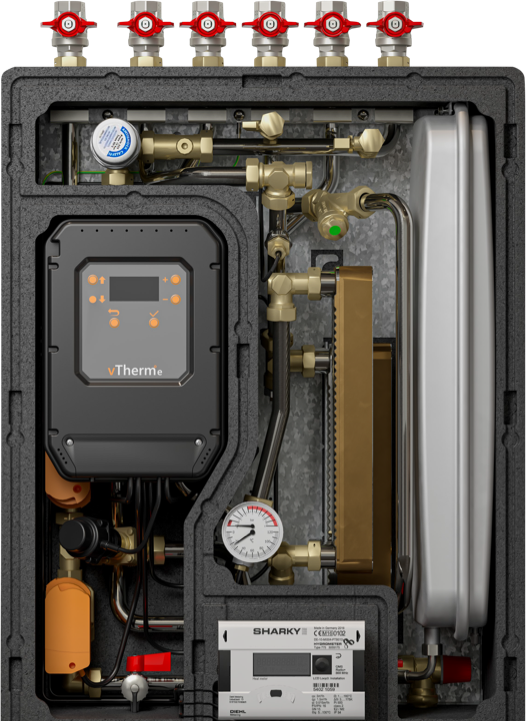

As some of the most efficient heat interface units on the market, the vTherm° heat interface units have been developed with a breadth of features designed to meet the requirements for all heat network, district heating and communal energy schemes.

vTherm˚ has proven performance on lower temperature networks and is heat pump compatible, supporting the industry to embrace next-generation district heating schemes.

Building on Vital Energi’s knowledge and two generations of experience in the heat network market, the vTherm°e (Stainless Steel) is BESA certified with one of the best results on the market.

Our vTherm° range has been developed to suit the majority of project requirements. However, should you require a bespoke unit, our team have the expertise and experience to develop and manufacture a unique solution for your project.